INDUSTRIES SERVED

Automotive and Industrial Manufacturing

The costs associated with errors and defects in automotive and industrial manufacturing can be significant, impacting various aspects of the production process, product quality, customer satisfaction, and brand reputation:

Rework and Scrap: Errors and defects in automotive manufacturing often require rework or result in scrapped parts or entire vehicles. Rework involves additional labor, materials, and time to correct defects, leading to increased production costs and reduced efficiency. Scrap represents wasted resources and materials, further adding to the financial burden.

Warranty Claims and Recalls: Defective vehicles or components may lead to warranty claims or product recalls, where manufacturers are required to repair or replace faulty parts at their expense. Warranty claims and recalls incur direct costs for replacement parts, labor, and logistics, as well as indirect costs associated with damage to brand reputation and customer loyalty.

Customer Dissatisfaction and Loss of Sales: Poor quality vehicles or components can result in dissatisfied customers, negative reviews, and loss of sales. Customers may experience reliability issues, safety concerns, or dissatisfaction with vehicle performance, leading them to choose competitors' products instead. The resulting decline in sales can have significant financial repercussions for automotive manufacturers.

Liability and Legal Costs: Defective automotive components or vehicles can pose safety risks to drivers, passengers, and other road users, potentially leading to accidents, injuries, or fatalities. Manufacturers may face legal claims, lawsuits, and liability settlements, incurring substantial legal expenses, damages, and reputational harm.

Supply Chain Disruptions: Errors and defects in automotive manufacturing can disrupt the supply chain, affecting upstream suppliers and downstream customers. Production delays, shortages of critical components, and disruptions to manufacturing operations can lead to lost revenue, penalties for missed deadlines, and strained relationships with suppliers and partners.

Ripple Effects on Brand Reputation: Quality issues and product recalls can tarnish the reputation of automotive brands, undermining consumer trust and brand equity. Negative publicity, social media backlash, and word-of-mouth referrals can have long-term consequences, impacting sales, market share, and brand loyalty.

Quality Control and Inspection Costs: To prevent errors and defects, automotive manufacturers invest in quality control measures, including inspections, testing, and quality assurance processes. These activities incur costs for equipment, personnel, training, and compliance with quality standards and regulations.

Lost Opportunities for Innovation and Growth: Focusing resources on addressing quality issues and rectifying defects may divert attention and resources away from innovation, product development, and strategic initiatives. Manufacturers may miss opportunities to introduce new features, technologies, or models that could drive growth and competitive advantage in the market.

In summary, errors and defects in automotive manufacturing entail direct and indirect costs that can impact profitability, customer satisfaction, and brand reputation. Detect-It’s AI Software gives manufacturers the power to create their own quality assurance and error proofing applications so they can mitigate the financial and operational risks associated with quality issues and enhance their competitiveness in the global automotive industry.

Detect-It AI Software can significantly enhance various aspects of the manufacturing process:

Defect Detection: Detect-It can inspect products in real-time on the production line to identify defects, imperfections, or abnormalities. This enables manufacturers to take immediate corrective actions, reducing scrap, rework, and waste. We call this “no faults forward.”

Quality Assurance: By analyzing visual data, Detect-It can ensure that products meet predefined quality standards. It can detect deviations from specifications and alert operators or automatically reject faulty items, ensuring consistent product quality.

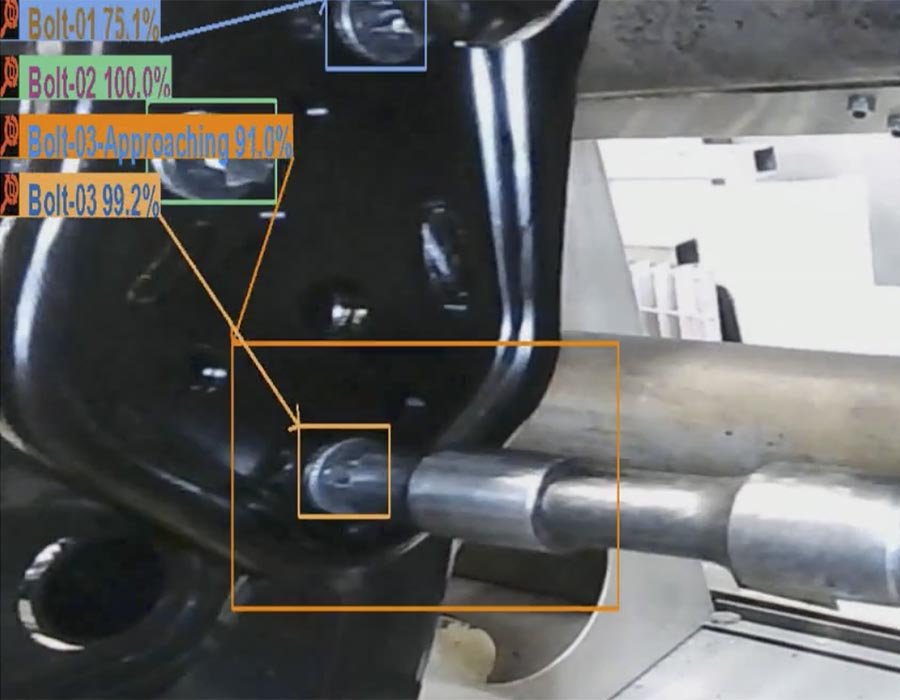

Component Inspection: Detect-It can inspect individual components or parts to verify their integrity, dimensions, or alignment. This helps prevent assembly errors and ensures that components meet quality requirements before integration into larger assemblies.

Equipment Monitoring: Detect-It can monitor machinery and equipment for signs of wear, damage, or malfunction by analyzing visual data from cameras or sensors. This enables predictive maintenance and minimizes unplanned downtime.

Safety Compliance: Detect-It can monitor the manufacturing environment for safety compliance, such as detecting unauthorized personnel in restricted areas or identifying potential safety hazards. This helps prevent accidents and ensures regulatory compliance.

Inventory Management: Detect-It use visual data to track inventory levels and monitor stock movements within the manufacturing facility. This enables real-time inventory management, ensuring that materials and components are available when needed and minimizing stockouts or excess inventory.

Product Traceability: Detect-It can provide traceability by capturing and analyzing visual data throughout the production process. This enables manufacturers to track the origin of components, monitor production history, and ensure product authenticity and compliance with regulatory requirements.

Detect-It Software can play a crucial role in improving quality, efficiency, safety, and profitability of your manufacturing process. Detect-It enables manufacturers to leverage visual data effectively to make informed decisions, reduce or eliminate errors, and drive operational excellence.

What Can Detect-It AI Do for Manufacturing?

Surface

Inspection

Automate surface inspection with human-like precision with Detect-It AI.

Tool

Geolocation

Make all your tools smart tools by knowing where they are in a build.

Assembly Verification

Ensure that every part is built correctly and that no faults get forwarded.

CUSTOMERS INCLUDE:

Click below to learn more about the Detect-It AI Software development platform.